Tortuous Path

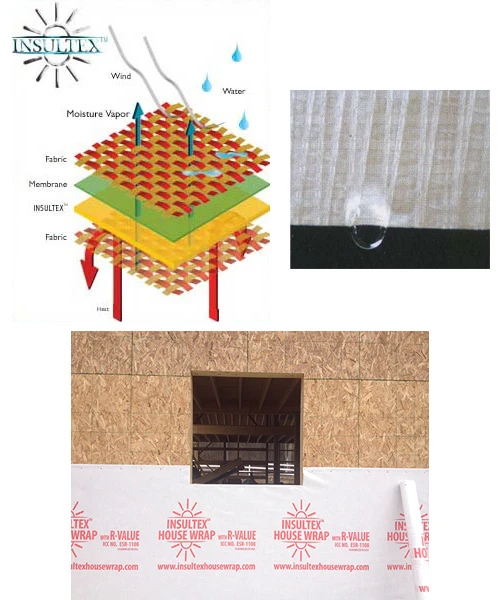

Insultex consists of a three-dimensional network of a countless number of evacuated cells, which impacts the conduction of thermal energy.

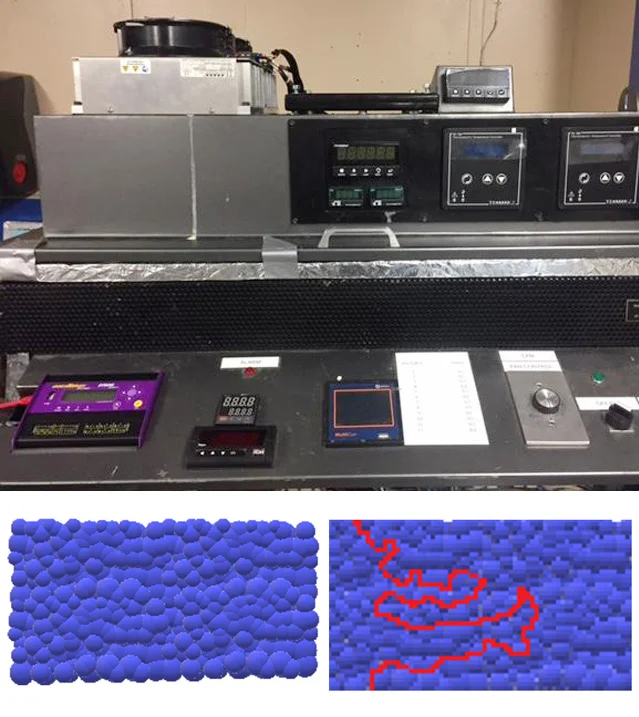

Insultex is a semi-crystalline, closed cell foam in which the cells are totally evacuated. This implies that the cells are small vacuum enclosures, stacked one on top of the other in a random fashion. At present, we understand that a vacuum is the best thermal insulator, better than aerogels and better than NIMs (nano insulation materials) such as HSNSs (hollow silica nano spheres). The low-pressure space and the structural integrity of the polymeric cellular network guarantees a high quality vacuum: therefore, it does not require much Insultex with respect to gage (thickness) to produce a respectable R-value. Moreover, through third party testing with gas chromatography, mass spectrometry, vapor analysis and gas pycnometry, we have confirmed the existence of a vacuum in our product.

The semi-rigid structure keeps the cell walls from collapsing and displays very good memory, thereby, good recovery when compressed. Therefore, the more evacuated cells that are stacked, the better the insulation properties. Insultex resists heat transfer. It has a low thermal conductivity and a high thermal resistance. It is important to note that Insultex is an evolutionary as well as revolutionary product that uses a modified ASTM C518 method, in which a 0.75 inch air gap is employed on both sides of the target material during the R-value testing phase. Insultex is recyclable, and a cost-effective way of saving energy, in new construction and retrofit.

Insultex House Wraps works. Here’s the proof:

The R- value results represent the product sample itself. The referenced ¾” air gaps of the modified ASTM C518- 10 test method are not a contributing factor of the material’s performance.